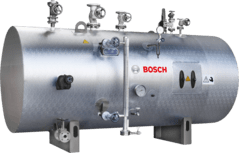

Steam boiler

Universal steam boiler ZFR, ZFR-X

The ZFR is a highly efficient double-flame tube boiler with a three-pass design for 18,000 to 55,000 kg/h of steam at up to 30 bar. Two independent firing units and flue gas paths offer very high flexibility thanks to a doubled modulation range.

- Double-flame tube boiler for 18,000 to 55,000 kg/h with very high efficiency across the entire power range

- Reliable solution for highly fluctuating steam demand

- Project-specific equipment and optional components, for example superheated steam generation

- Future-proof with options for low-NOx and CO2-neutral operation

- Smart boiler control and seamless system integration

- Stable supply and durable design Made in Germany

Benefits

Very high efficiency across the entire power range

The ZFR is known for its high efficiency at each output stage. Combining with an integrated economiser further increases the efficiency. An optional condensing heat exchanger for the residual waste heat also reduces the fuel demand. Extremely low emissions (to below 50 mg NOx) are possible thanks to the large furnace.

Reliable solution for highly fluctuating steam demand

The boiler's flue gas paths and firing units are completely separate from one another. This doubles the modulation range and protects the burner through continuous operation as well as significantly lower activation and deactivation cycles. The ZFR reliably meets dynamic output requirements and generates process heat highly efficiently, even in partial load areas.

Project-specific equipment and optional superheated steam generation

The boiler is individually configured, produced and equipped for your specific application. You receive a complete system with coordinated equipment, effective heat insulation and pre-configured control. The optional superheater module makes the ZFR-X suitable for superheated steam generation for large industry or power plants.

Future-proof with options for low-NOx and CO2-neutral operation

The ZFR can be used individually with various fuel types and sustainably reduces emissions in its low-NOx version. It can also operate with hydrogen, biogas or bio-oil, or as a hybrid using green electricity. The CO2-neutral fuel design can be implemented either at the factory or later for retrofitting.

Smart boiler control and seamless system integration

The Bosch BCO and SCO boiler controls include intelligent control features for fully-automated boiler operation and easy connection to your process control system. An optional digital efficiency assistant and protected remote access are available for seamless Industry 4.0 integration.

Stable supply and durable design Made in Germany

Thanks to the high steam chamber and three-component control, the ZFR offers excellent pressure consistency and steam quality. The proven German-made construction is highly durable and robust. The result is a reliable heat and process heat generation system from Bosch.

Technical Details and Documents

Choose product variant

-

Documents

Steam boilers brochure Download now -

Technical data

Heat transfer medium High-pressure saturated steam

Design Three-pass double-flame tube/smoke tube technology

Output 18,000 to 55,000 kg/h

Safety pressure up to 30 bar

Max. temperature up to 235 °C

Energy source Gas, oil, bio gas, bio oil, hydrogen